Menu

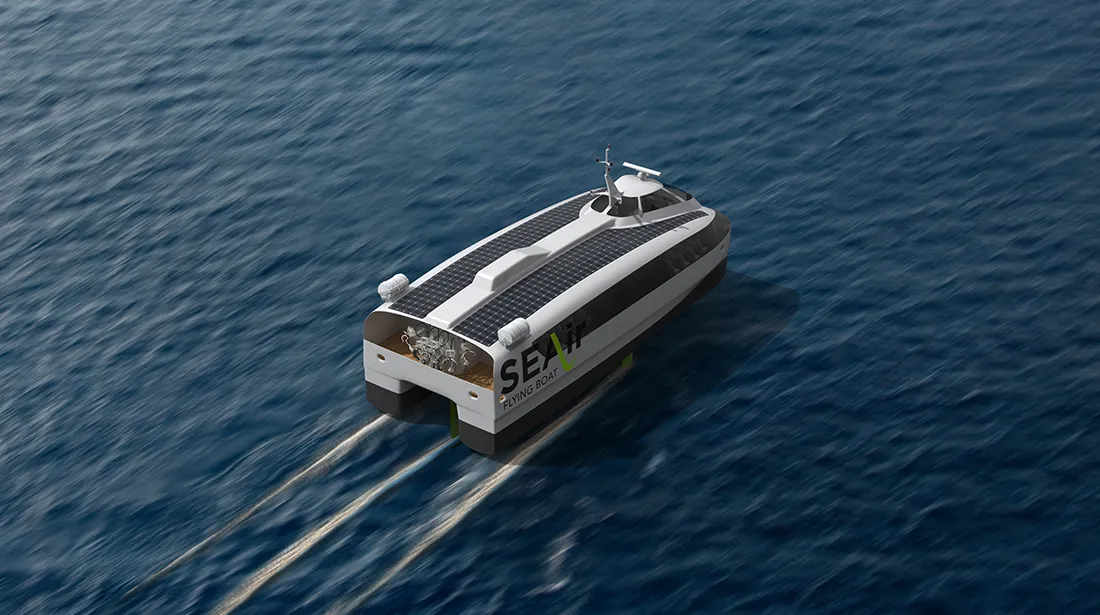

SEAir Solutions is a naval design and engineering company

Since 2016, SEAir Solutions has built up extensive and proven expertise:

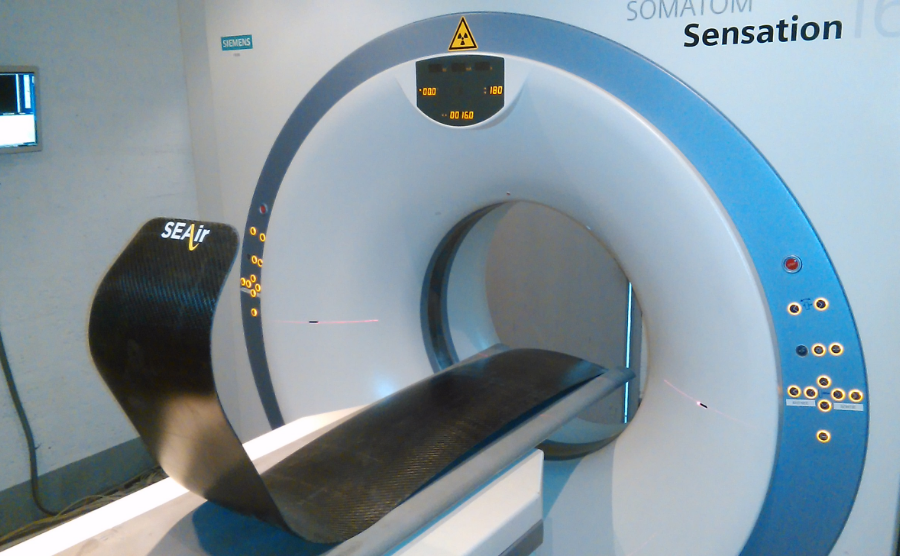

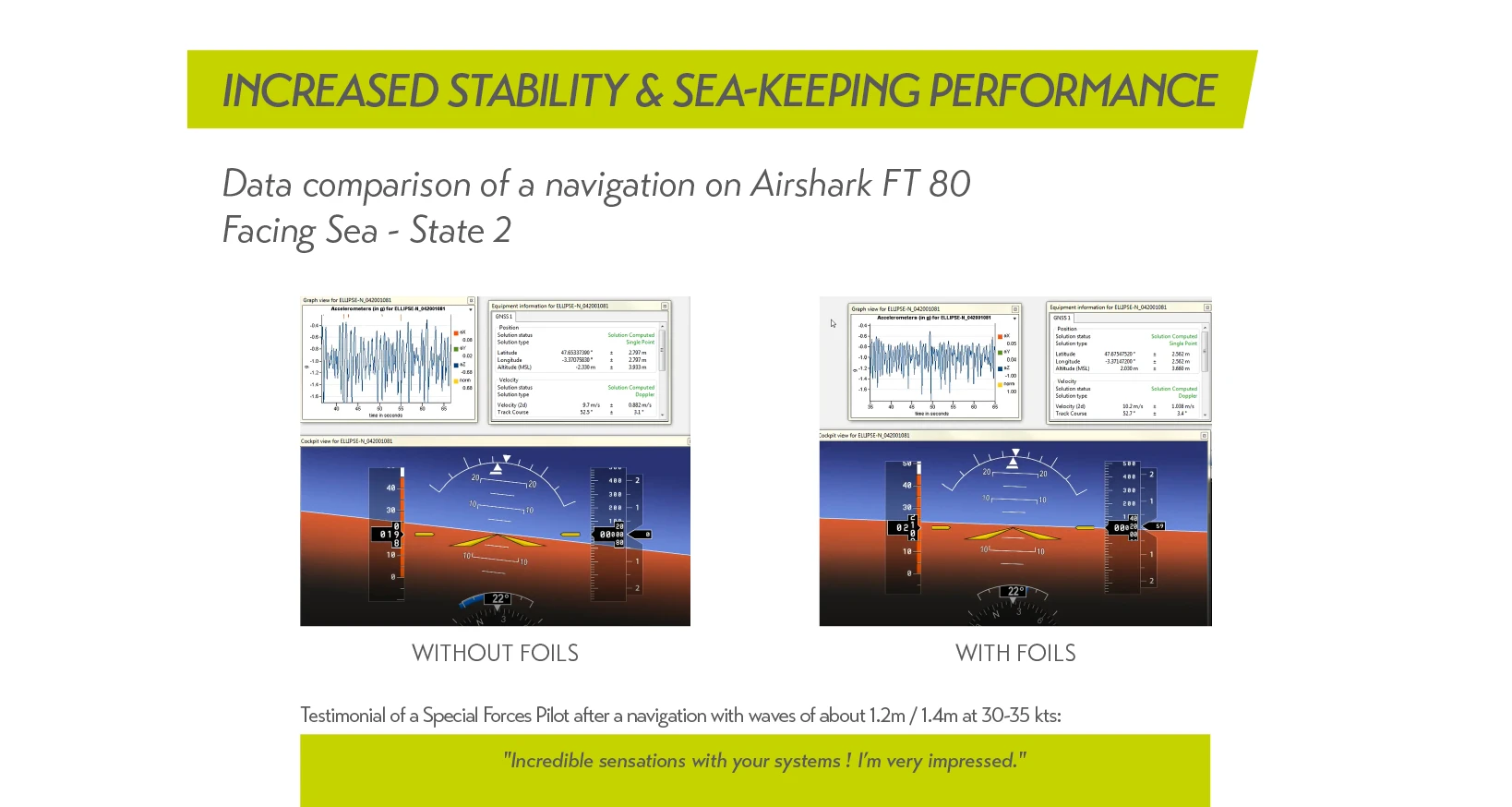

Validation of our R&D through an extensive number of sea trials. Our innovative hydrofoil systems are built to be robust and user-friendly. Each system is custom design according to specification and usage, in collaboration with your boat builder, naval architect, project manager, etc.

We offer our clients a turnkey solution: from design and manufacture to sea trials, commissioning, and maintenance.

A fine-tuned combination of five skills mastered by our team of experts to achieve high-performance in-flight mode:

Speed

Sea Performance

Simple and Safe usage

Stability and Safety

Equipment supply

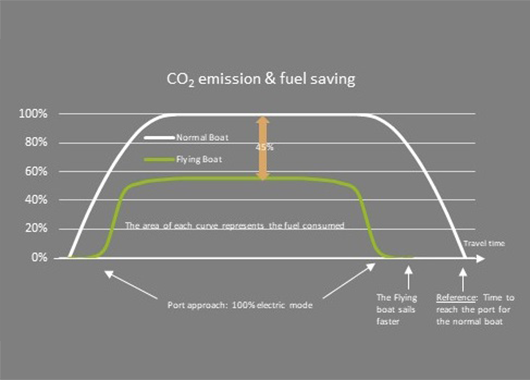

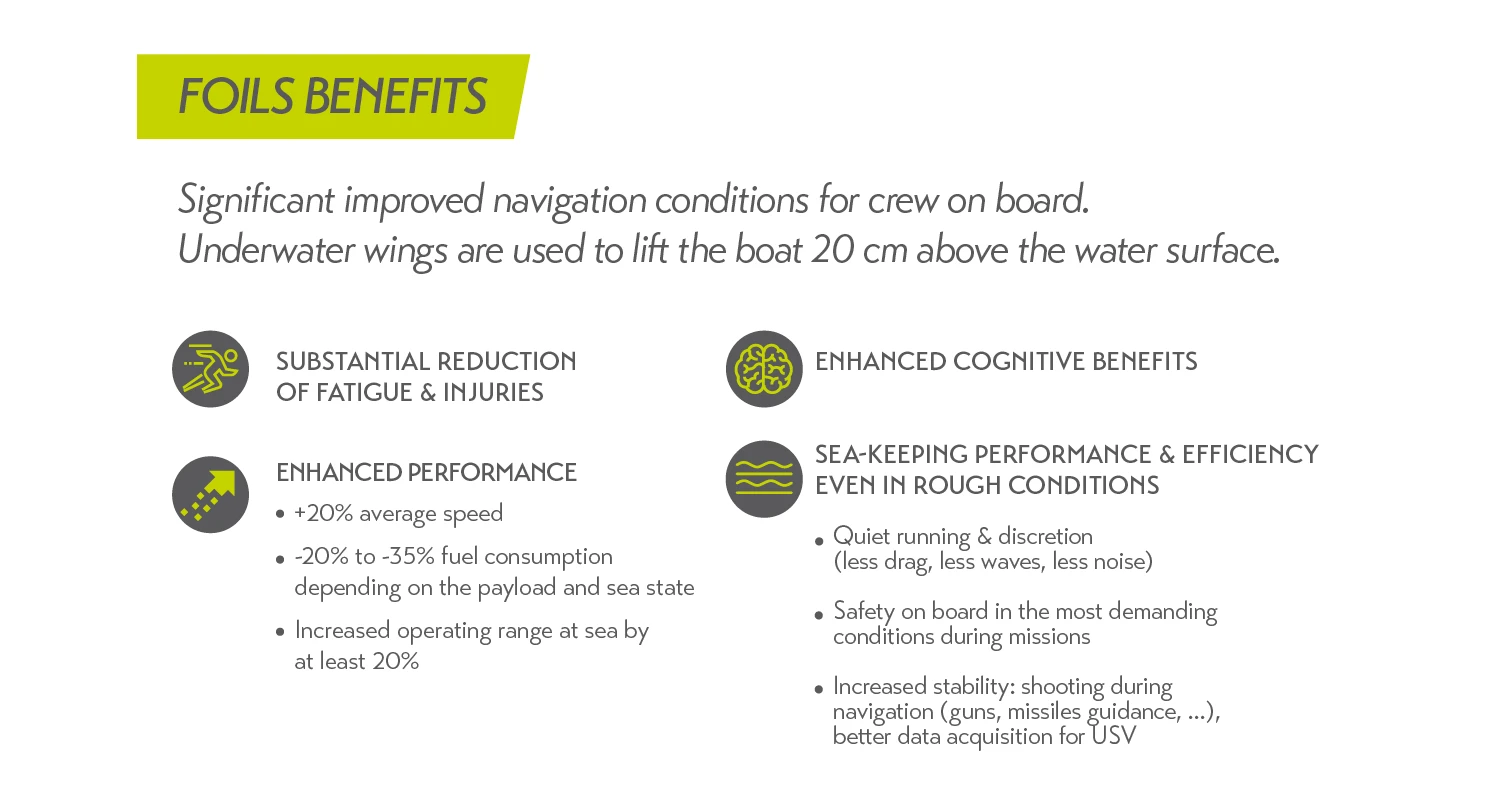

Hydrofoils lift the boat, allowing a drastic reduction of the drag and wake. The key benefits are:

Our hydrofoil systems can be integrated regardless of the power supply: conventional, hybrid diesel electric, full electric, etc.

Hydrofoil systems provide key benefits for operators

and passengers:

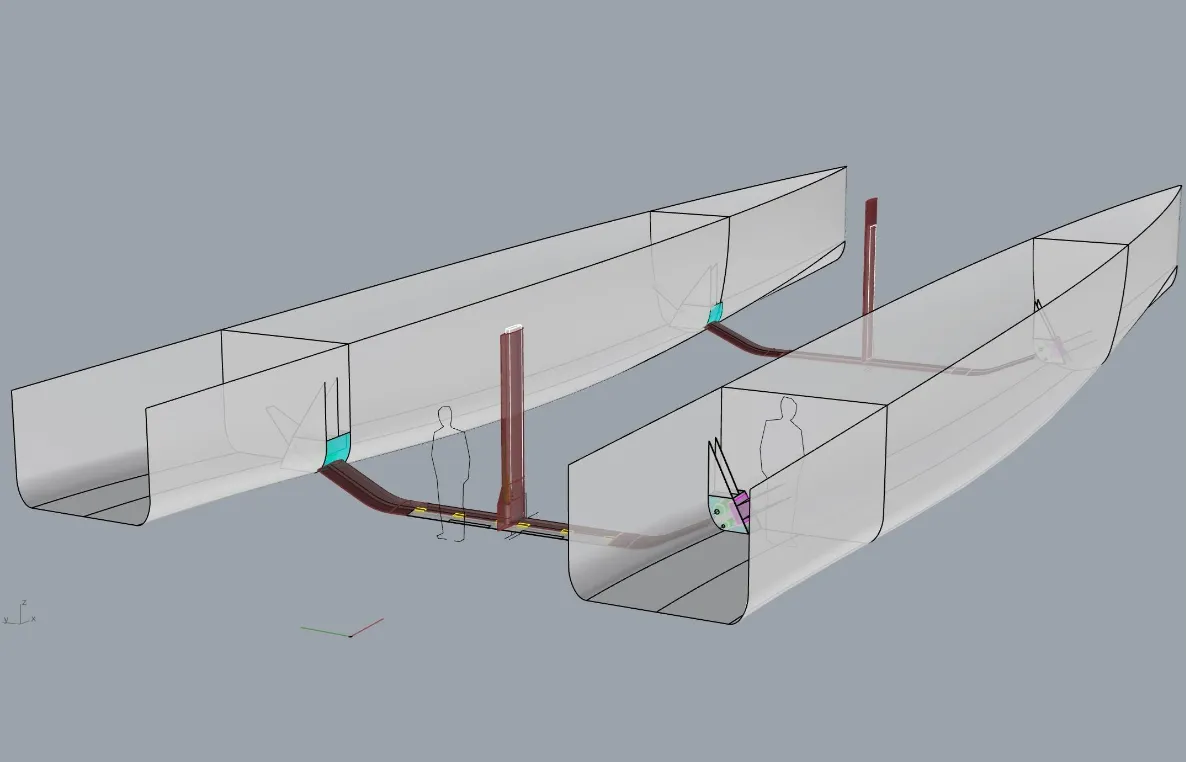

We offer to our clients complete support throughout the process, from preliminary design to detailed design phases, manufacture and sea trials to commissioning and beyond.

When designing a flying boat, all manufacturing processes and equipment that improve sustainability are carefully considered:

CTV ZEST FOR LOUIS DREYFUS ARMATEUR

DAILY MARITIME TRANSPORT OF 18M

IN PARTNERSHIP WITH MAURIC (NAVAL ARCHITECT)

Hydrofoil systems provide key benefits:

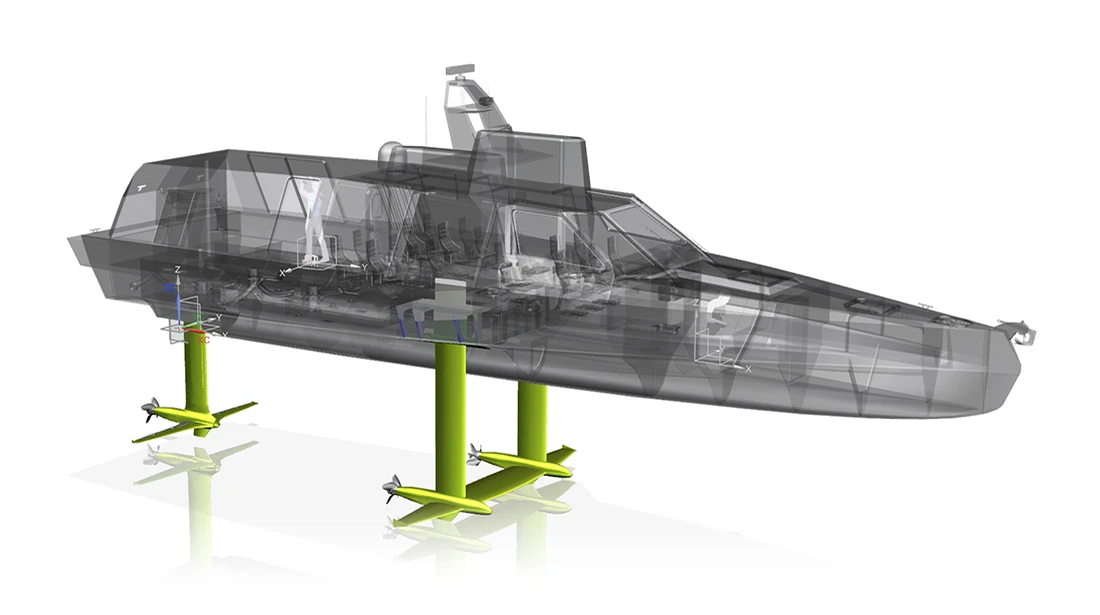

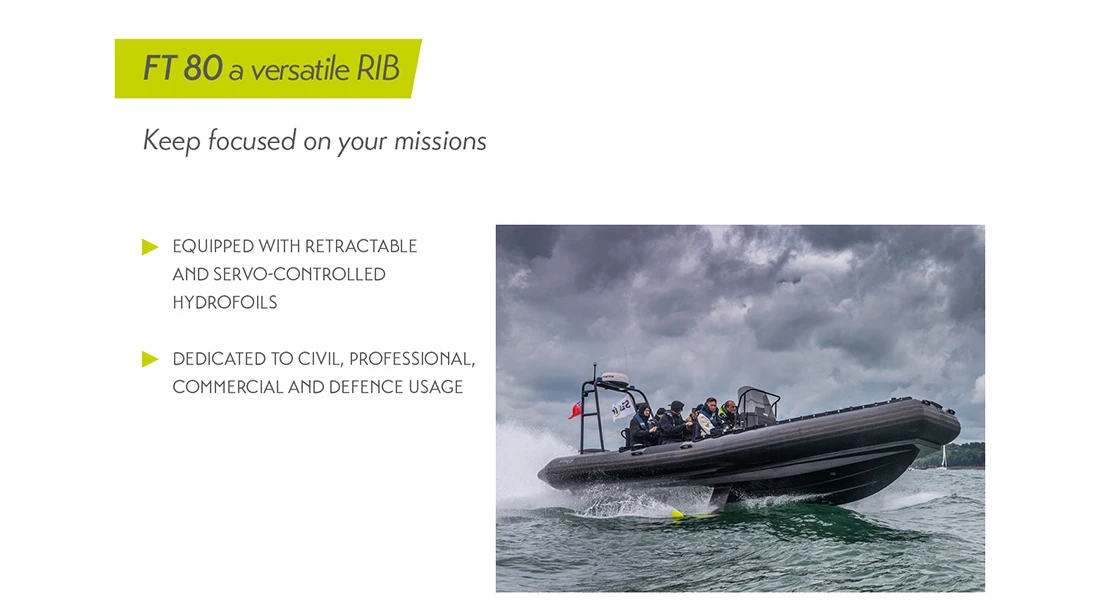

SEAir can design fully customised Flying Boats (RIB or Rigid Hull):

Examples of projects:

Clients categories: Professional, Passenger Transfers, Safety, Survey, NGO, Defence, Yachting

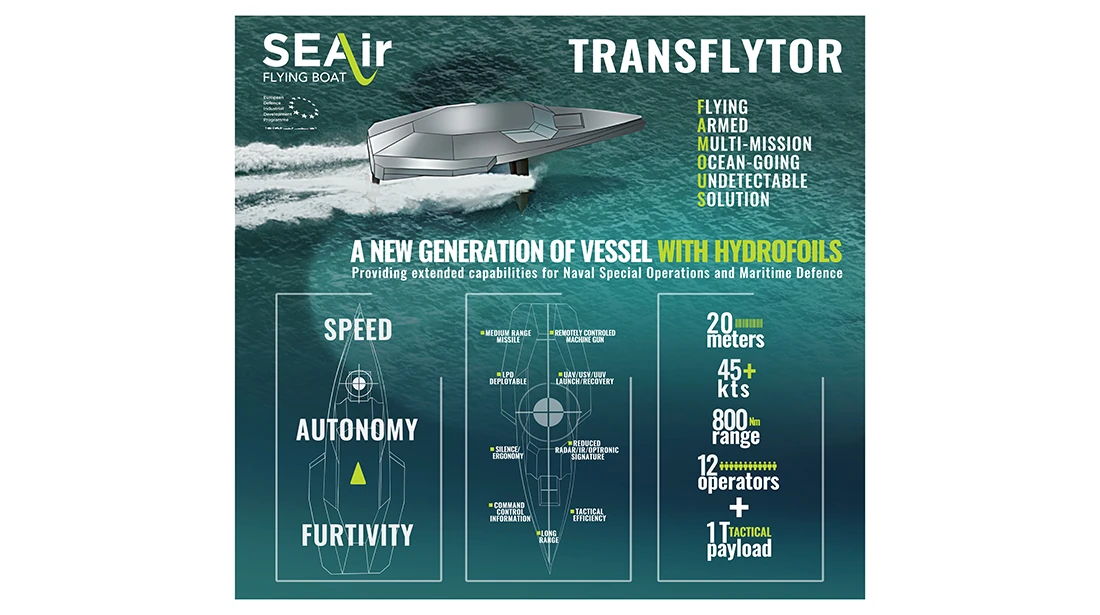

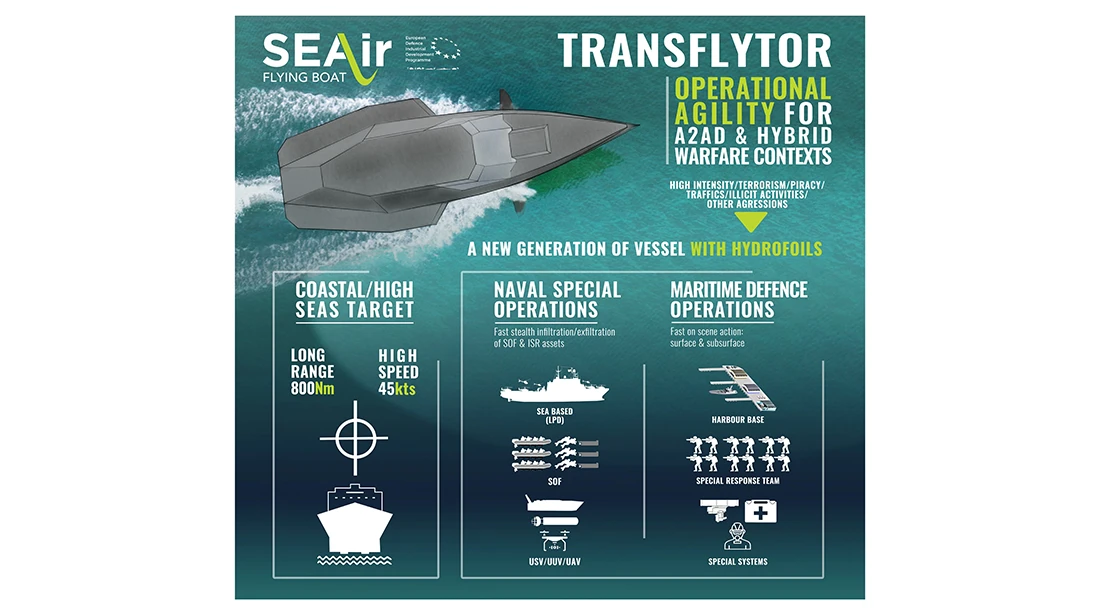

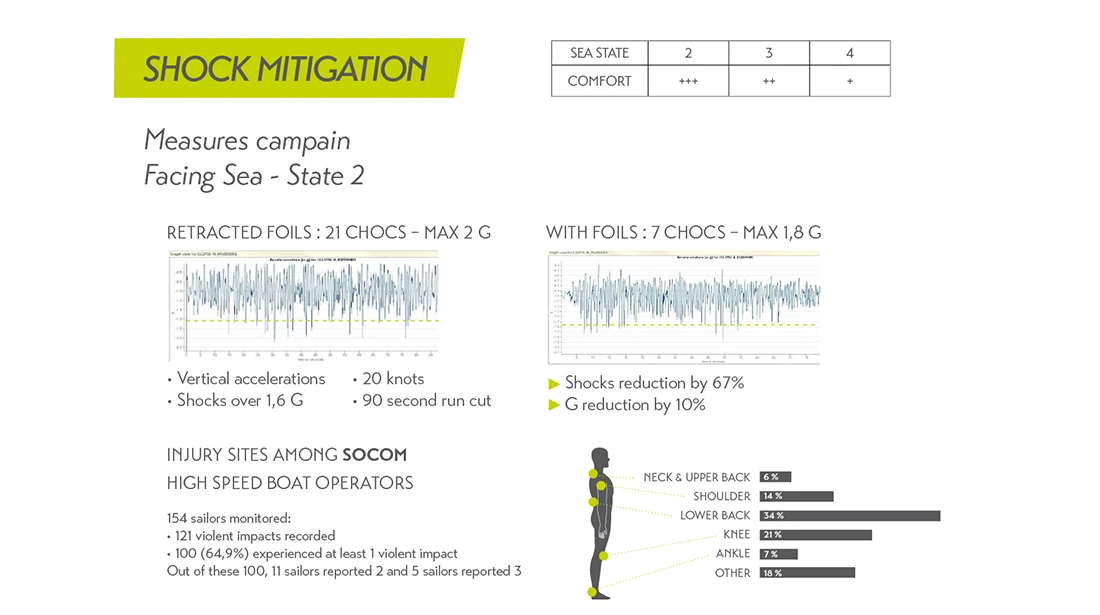

Stealth - Speed – Extended range – Shock Mitigation

With hydrofoils boats:

Our team works closely with an Admiral Defence Adviser, a former Commander of Special Forces. He assists us to ensure that the systems we design meet the demanding operational requirements of the defence sector, such as:

Our completed and current projects include retractable hydrofoils to ensure the versatility of your missions:

Sign up for our newsletter and stay up to date with SEAir’s latest news and innovations

© 2023 SEAir solutions. All right reserved.